3D Baskı Çiftliği Kurma ve Sürdürme Rehberi

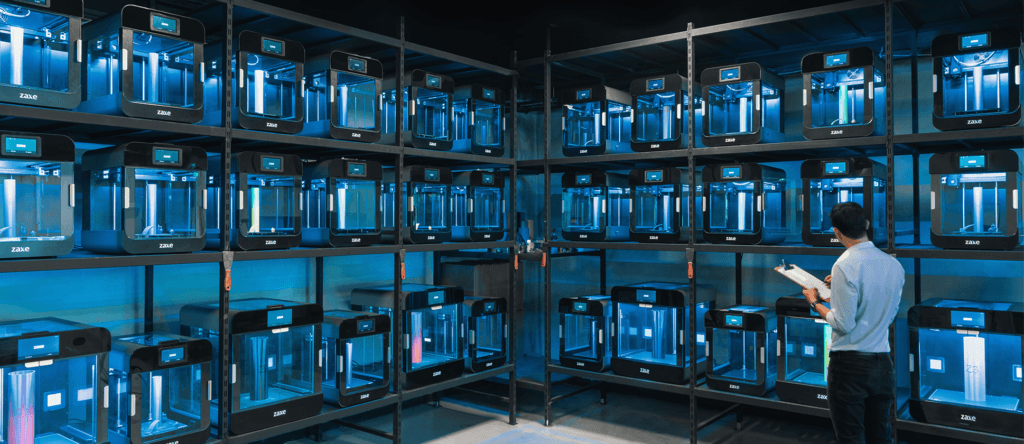

3D Baskı Çiftliklerine Giriş

3D baskı teknolojisindeki hızlı gelişmeler, bu yöntemi yalnızca bir hobi olmaktan çıkararak birçok sektörde önemli bir üretim stratejisi haline getirdi. Bu dönüşüm, birden fazla yazıcının kullanıldığı ve dinamik bir üretim hattı oluşturan 3D baskı çiftlikleri kavramını ortaya çıkardı. 3D baskı çiftlikleri, yalnızca parçalar üretmekle kalmaz, aynı zamanda diğer işletmelere geniş kapsamlı hizmetler sunarak esnekliği ve verimliliğiyle dikkat çeker.

Neden 3D Baskı Çiftliği Kurmalısınız?

Birden fazla 3D yazıcıya sahip girişimciler ve işletmeler için bu varlıkları kârlı bir girişime dönüştürmek oldukça mantıklıdır. 3D baskının "kendin yap" doğası ve düşük başlangıç maliyetleri, bu modeli cazip hale getirir. Bu yaklaşım yalnızca üretimle sınırlı kalmaz; aynı zamanda, cihazlara nadiren ihtiyaç duyan işletmelere baskı hizmeti sunarak ek bir iş modeli oluşturur.

3D Baskı Çiftliği Kurulumunda Dikkat Edilecek Hususlar

Bir 3D baskı çiftliği kurmadan önce, maliyetler, zorluklar ve pazar dinamiklerini anlamak için dikkatli bir planlama yapmak önemlidir.

- 3D Yazıcı Seçimi: Yüksek kaliteli parçalar için endüstriyel düzeyde yazıcılar gerekebilir. Bu yazıcılar genellikle 10.000 dolar ve üzeri fiyatlara sahiptir. Daha az talepkar uygulamalar için, 1.000 ila 4.000 dolar arasında fiyatlara sahip orta sınıf yazıcılar yeterli olabilir.

- Operasyonel Ölçek: Operasyonlarınızın ölçeği, pazar talebi ve büyüme potansiyeliyle uyumlu olmalıdır.

- Bütçeleme: Başlangıç maliyetleri (yazıcı satın alımı, çalışma alanı) ve operasyonel maliyetler (malzemeler, elektrik, bakım) dikkatlice planlanmalıdır.

Başarılı Bir 3D Baskı Çiftliği İçin Adımlar

- Ürün Seçimi: Hangi ürünleri basacağınızı belirleyin.

- Müşteri Bulma: Operasyonlarınızı başlatmadan önce potansiyel müşteriler bulun.

- Çalışma Alanı Ayarlama: Yazıcılar için uygun bir alan seçin.

- Ekipman Satın Alma: Yatırım maliyetini optimize etmek için yeni veya ikinci el seçenekleri değerlendirin.

- Verimlilik Planlama: Çıktıyı en üst düzeye çıkarmak için üretim takvimi oluşturun.

- Dijital Varlık Oluşturma: Hedef kitlenize ulaşmak için etkili bir web sitesi tasarlayın.

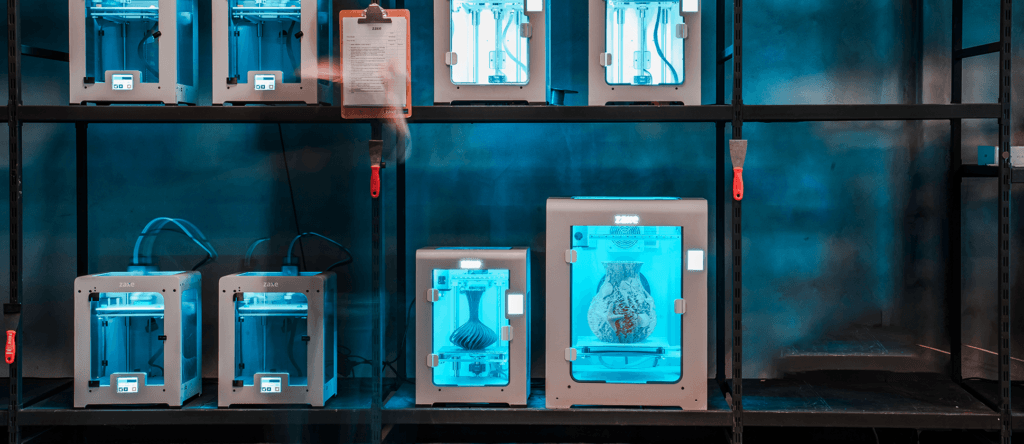

Zaxe 3D Yazıcılarını Tercih Etmek İçin Sebepler

Zaxe 3D yazıcıları, ileri teknoloji ve üstün müşteri hizmetleriyle bilinir. Bu yazıcılar, üretkenliği artırarak operasyonel verimliliği destekler. Zaxe'ye yatırım yapmak, kaliteden ve destekten ödün vermemek anlamına gelir.